Modcon Systems Unveils AI-Integrated Analyzer Platform for Real-Time Process Optimization

Modcon.AI platform integrates real-time data from process analyzers with artificial intelligence to enable adaptive control, predictive optimization, and enhanced safety across hydrogen and refining industries.

For decades, industrial optimization relied on historical process data, model-based simulations, and post-event analysis. While effective under steady conditions, these methods often lag behind the dynamic reality of today’s energy sector—where fluctuating feedstock quality, variable renewable inputs, and tightening environmental regulations demand continuous adaptability. The new Modcon.AI platform addresses this challenge by merging verified real-time analyzer measurements with deep-reinforcement learning (DRL) to deliver adaptive control decisions within milliseconds.

This convergence of measurement and intelligence ensures that AI operates not on assumptions, but on live physical data that reflect the actual process state. The result is a system that improves energy efficiency, enhances product quality, reduces emissions, and reinforces plant safety—all in real time.

“Industrial AI becomes meaningful only when grounded in continuous and accurate measurement,” said Gregory Shahnovsky, CEO of Modcon Systems. “By connecting our MOD-series analyzers directly with adaptive learning models, we transform raw data into actionable intelligence that allows plants to run cleaner, safer, and smarter.”

The Modcon.AI platform leverages Modcon’s field-proven analyzers—including the MOD-1040 Optical Oxygen Analyzer, MOD-1060 Hydrogen Analyzer, and Beacon-3000 NIR Process Analyzer—all designed for harsh operating environments and certified to ATEX/IECEx Zone 1 and SIL-2 functional safety standards. These analyzers continuously measure oxygen, hydrogen, and hydrocarbon streams composition in high-pressure, high-temperature and corrosive streams, ensuring reliable performance where conventional instruments often fail.

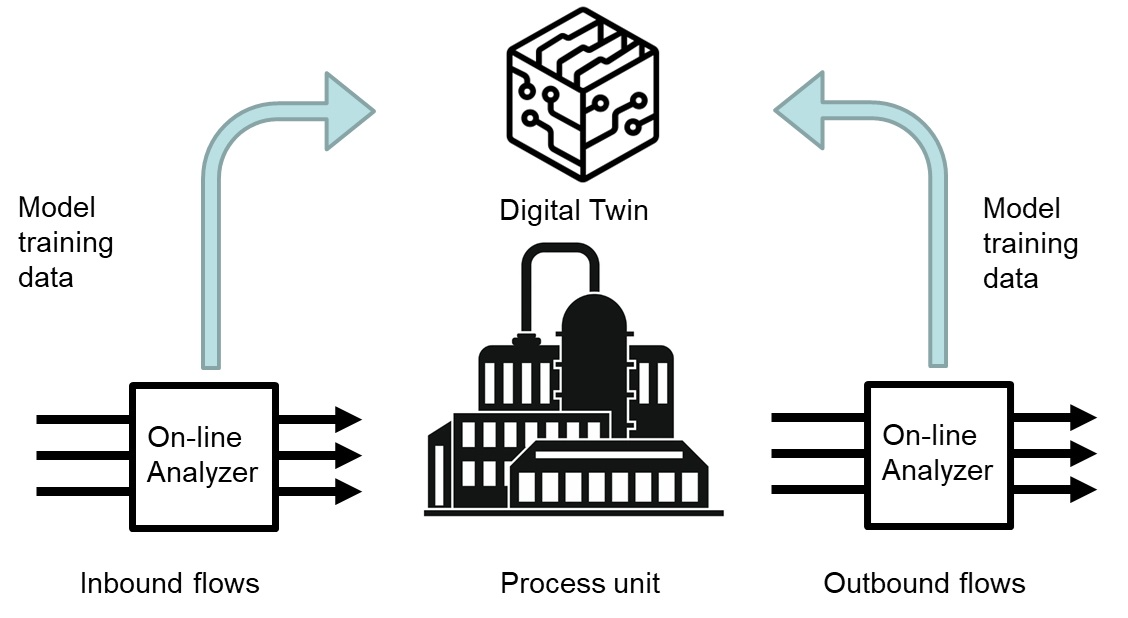

Through secure Modbus and Ethernet communication protocols, analyzer data is transmitted to the Modcon.AI edge-analytics layer, where advanced neural networks process multiple input streams, detect anomalies, predict process deviations and recommend corrective actions. This architecture effectively closes the loop between measurement and control, allowing production units to self-adjust while maintaining human oversight and safety compliance.

Initial pilot implementations in refinery and hydrogen production units have demonstrated measurable impact:

* Up to 15% reduction in process variability, resulting in smoother operations and lower waste.

* 8% decrease in CO₂ emissions through optimized feedstock blending and combustion control.

* Extended catalyst life and reduced unplanned downtime through early anomaly detection.

The system’s design also enables predictive maintenance. By continuously monitoring process conditions and products quality, Modcon.AI alerts operators before process failures or fouling events occur—reducing maintenance costs and improving uptime. This predictive layer is built upon Modcon’s decades-long experience in field instrumentation, ensuring that AI insights remain rooted in the realities of industrial operations.

Beyond individual plant performance, Modcon.AI enables enterprise-level optimization. Plant operators can benchmark multiple facilities, compare efficiency indicators, and simulate “what-if” scenarios to evaluate the impact of operational changes on yield, energy use, and emissions. The modular platform is compatible with existing DCS, PLC, and cloud environments, offering flexible deployment across on-premise and hybrid architectures. All communication layers follow IEC 62443 cybersecurity standards, guaranteeing secure integration within critical infrastructure.

Shahnovsky emphasized that this development aligns with global efforts toward decarbonization and the energy transition: “Our mission is to make real-time data not just visible but actionable. Industrial decarbonization will not happen by adding more sensors—it requires intelligent analyzer systems that understand and react instantly. Modcon.AI is our contribution to achieving measurable sustainability through precision and automation.”

With over five decades of innovation in process analysis, Modcon Systems has supplied thousands of analyzers and optimization solutions across refineries, petrochemical complexes, and energy facilities worldwide. The new platform extends this legacy by adding an intelligent layer that connects measurement, predictions and control—representing a major step toward autonomous industrial operation.

By embedding AI into analyzer networks, Modcon positions itself at the forefront of Industry 4.0 and the emerging “Industrial Internet of Intelligence” (IIoI)—a paradigm where analyzers, controllers, and digital twins operate as a unified ecosystem. The company envisions this technology driving long-term improvements in safety, efficiency, and profitability for industrial producers globally.

Customers are invited to participate in pilot projects and upgrade programs, particularly for offshore and hazardous-area hydrogen applications where reliable oxygen and hydrogen monitoring are essential for process safety. For more information or to request participation in Modcon’s AI-optimization pilot program, visit

👉 https://modcon.group/contact/

About Modcon Systems Ltd.

Founded in 1972, Modcon Systems Ltd. provides advanced process-analyzer and AI-optimization solutions for refineries, petrochemical plants, and green-hydrogen production facilities. The company’s portfolio includes optical, thermal-conductivity, near-infrared, and petroleum analyzers, as well as integrated analyzer systems and digital optimization platforms. With headquarters in the UK and R&D located in Israel, and a global network of partners, Modcon delivers comprehensive solutions designed to increase yield, reduce emissions, and ensure safe, efficient operation across industrial sectors worldwide.

Anya Alter

Modcon Systems Ltd.

+44 20 4577 1737

email us here

Visit us on social media:

LinkedIn

YouTube

AI-Driven Energy Optimization to Cut Industrial Costs and Emissions

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.